Non-traditional machining processes can directly utilize various forms of energy to remove material from in workpiece. For example, AJM, USM, WJM and AWJM processes are based on mechanical energy; CHM is based on chemical energy; ECM is based on electrochemical energy; and EDM, LBM, PAM and EBM are based on thermal energy. Since Electron Beam Machining (EBM) is one thermal energy based process, so here material is removed by melting and vaporization. It employs a concentrated and focused beam of electrons as heat source. Ample electrons are first generated using an electron gun and are accelerated in an electric field. Electrons are then concentrated in the form of a beam and directed towards the workpiece surface. When these high velocity electrons strike the work surface, their kinetic energy gets converted into thermal energy. Accordingly, immense heat is generated within a fraction of a second that increases localized temperature as high as 10,000°C. Such a high temperature ultimately leads to the melting and vaporization of workpiece material beneath the incidental beam. EBM can be advantageously employed for cutting, profiling and drilling on electrically conductive samples only.

Electrochemical Machining (ECM) is completely different process than the Electron Beam Machining (EBM). ECM is based on electro-chemical energy where material removal takes place in the form of ions owing to electro-chemical dissolution. The process mandatorily requires a form tool made of electrically conductive material. The profile or shape of the tool should be in accordance with the intended feature (because the inverse profile of the feature is finally imparted on the workpiece). The workpiece should also be electrically conductive one. Here the tool and workpiece are made two electrodes of an electro-chemical cell and these are immersed with appropriate electrolyte fluid. A small gap (usually few microns) is always maintained between two electrodes. When sufficient voltage is applied across the two electrodes, ionic dissolution initiates according to the Faraday’s Law of electro-chemical dissolution. The tool material and electrolyte are chosen in such a way that material removal takes place only from the workpiece electrode, while the tool and electrolyte remain intact. ECM is a very slow process but it offers several advantages like good surface finish, no mechanically or thermally induced stress, etc. Various similarities and differences between Electron Beam Machining (EBM) and Electrochemical Machining (ECM) are given below in table format.

Similarities between EBM and ECM

- Both EBM and ECM are non-traditional machining processes. None of them is hybrid process.

- Both the processes are applicable to electrically conductive workpiece materials only.

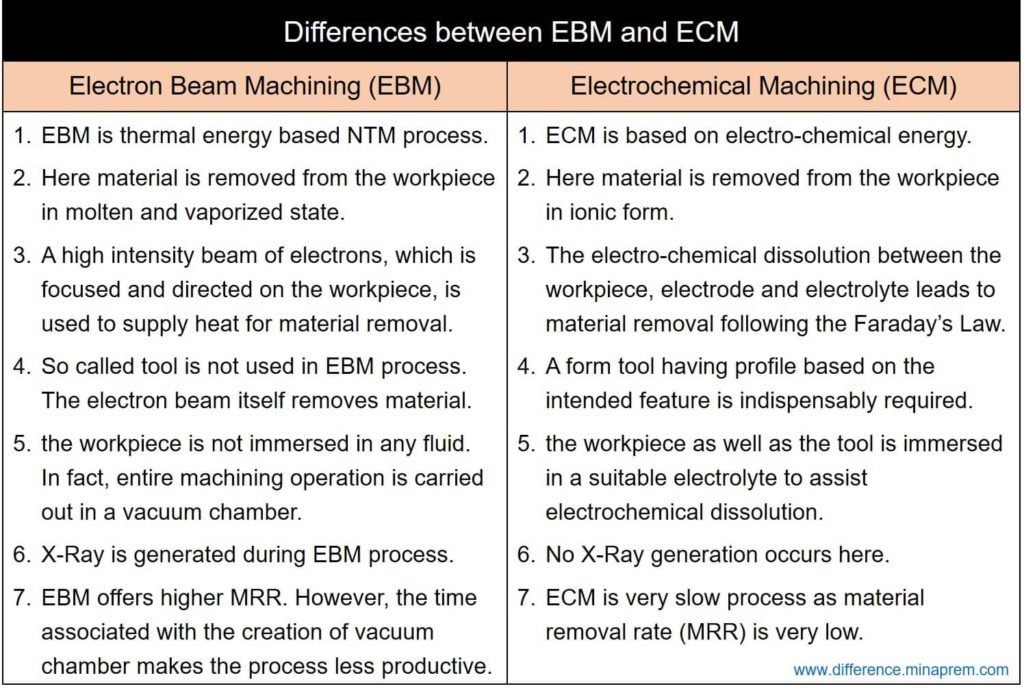

Differences between EBM and ECM

| Electron Beam Machining (EBM) | Electro-Chemical Machining (ECM) |

|---|---|

| EBM is thermal energy based non-traditional machining process. | ECM is electro-chemical energy based non-traditional machining process. |

| Here material is removed from the workpiece in molten and vaporized state. | Here material is removed from the workpiece in ionic form (i.e. in the form of ions) caused by electro-chemical dissolution. |

| A high intensity beam of electrons, which is focused and directed on the workpiece, is used to supply heat for material removal. | The electro-chemical reaction between the workpiece, electrode and electrolyte under the presence of external voltage leads to material removal following the Faraday’s Law. |

| So called tool electrode is not used in EBM process. The electron beam itself removes material. | A form tool having profile based on the intended feature is indispensably required to carry on electro-chemical reaction. |

| Here workpiece is not made any electrode. However, it is grounded to maintain electrical neutrality by dispensing striking electrons. | Here workpiece is made one electrode. However, its polarity is selected based on tool material and electrolyte. |

| In EBM, the workpiece is not immersed in any fluid. In fact, entire machining operation is carried out in a vacuum chamber. | In ECM, the workpiece as well as the tool is immersed in a suitable electrolyte to assist electrochemical dissolution. |

| During EBM process, X-Ray generation takes plane. It possesses health risk to the operator. | No such X-Ray generation takes place during ECM process. |

| Material removal takes place from all such points on the workpiece where the electron beam is focused. | Ionic dissolution rate is faster at the closest point between tool and workpiece. Thus surface asperities and waviness influence the dissolution rate significantly. |

| EBM offers higher material removal rate (MRR). However, the time associated with the creation of vacuum chamber makes the process less productive. | ECM is very slow process as MRR is very low. |

| Quality of the machined surface is affected by the presence of recast layer. | No such recast layer formation takes place here. |

| Since it is a thermal process, so a narrow Heat Affected Zone (HAZ) exists surrounding the machined feature. | No HAZ exists here as temperature remains close to room temperature during the process. |

| It offers high aspect ratio. Thus features like holes, deep pockets, etc. can be fabricated by EBM. | ECM is not suitable process to fabricate features having high aspect ratio due to the inherent chance of tapering. |

References

- Unconventional Machining Processes by T. Jagadeesha (I. K. International Publishing House Pvt. Ltd.).

- Advanced Machining Processes by V. K. Jain (Allied Publishers Private Limited).

- Nonconventional Machining by P. K. Mishra (Narosa Publishing House).