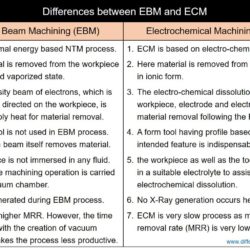

Difference Between EBM and ECM – Electron Beam Machining & Electrochemical Machining

Non-traditional machining processes can directly utilize various forms of energy to remove material from in workpiece. For example, AJM, USM, WJM and AWJM processes are based on mechanical energy; CHM is based on chemical energy; ECM is based on electrochemical energy; and EDM, LBM, PAM and EBM are based on thermal energy. Since Electron Beam Machining (EBM) is one thermal energy based process, so here material is removed by melting