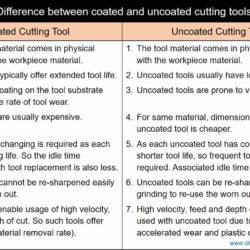

Difference Between Coated and Uncoated Cutting Tool in Metal Cutting

Cutting tool is a part and parcel in every conventional machining process. Tool material and geometry are two active parameters that influence process capability and machinability. For uninterrupted material removal, the tool material should be harder than the workpiece material. In addition to the hardness, tool material should ideally possess certain common properties, such as high strength, high toughness, high fatigue strength, shape retention capability at high temperature, high thermal