An electrode acts as one of the two terminals of an electric circuit to establish the electrical connection. It is always made of electrically conductive material so that it can easily emit or receive electrons or ions. Based on the polarity, an electrode can be either anode or cathode. A cathode is considered as negatively charged electrode as it liberates electrons, while an anode is considered as positively charged electrode as it receives electrons. Certain welding processes (mainly arc welding and resistance welding) processes utilize two electrodes for different purposes. In arc welding, the workpieces (which are required to join) are made one electrode, while another dedicated electrode is used to complete the electrical circuit. Here, the dedicated electrode can be given either positive or negative polarity. Accordingly, straight and reversed polarity exist in arc welding. Based on the polarity, the arc welding electrode either supplies or receives ample electrons continuously in order to form the arc. This arc is the primary source of heat that is indispensably required for fusing and joining two or more components. It is to be noted that in resistance welding two dedicated electrodes are used, which are periodically connected via the conductive samples to allow the electrons to flow through it and to generate heat by resistance heating in order to form the nugget.

Electric discharge machining (EDM) also employs an electrode; however, the shape and purpose are completely different from that used in welding. In EDM, a form electrode is used and it is always given negative polarity. The conductive workpiece is made another electrode. Two electrodes are always separated by a small gap, and this gap is usually immersed with suitable dielectric fluid. This dielectric normally acts as insulator; however, when breakdown voltage is applied across two electrodes, the dielectric breaks down leading to the flow of avalanche of electrons for a very short period of time. Accordingly, spark is generated (instead of an arc). Moreover, the EDM electrode is always non-consumable and thus form of the electrode remains intact for longer duration. Various similarities and differences between arc welding electrode and EDM electrode are given below in table format.

Similarities between arc welding electrode and EDM electrode

- High electrical conductivity is one desired property of the electrode material for both the cases.

- In both the cases, the electrode must emit electrons uniformly and steadily at minimum potential.

- In both the cases, the sample is made another electrode. Thus the sample material should also be electrically conductive one.

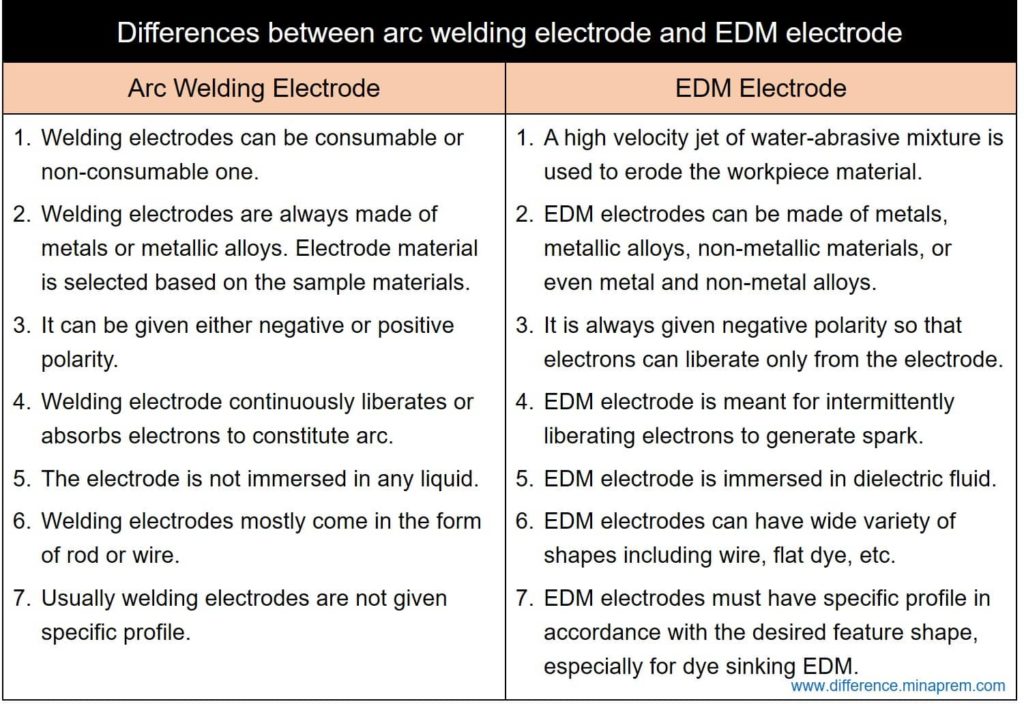

Differences between arc welding electrode and EDM electrode

| Arc Welding Electrode | EDM Electrode |

|---|---|

| Welding electrodes can be consumable or non-consumable one. A consumable electrode melts down and deposit on the weld bead to supply filler material during welding. | EDM electrode is always non-consumable. Thus this electrode does not melt down or deposit on workpiece surface during the process. |

| Welding electrodes are always made of metals or metallic alloys (like mild steel, tungsten, etc.). | EDM electrodes can be made of metals, metallic alloys, non-metallic materials, or even metal and non-metal alloys (like copper, brass, tungsten, graphite, etc.). |

| It can be given either negative or positive polarity. In fact, welding can be carried out in three different polarities – AC, DCEN and DCEP. | It is always given negative polarity. |

| Welding electrode is meant for liberating (or absorbing, based on polarity) electrons continuously to constitute arc. | EDM electrode is meant for liberating electrons intermittently to generate spark. |

| The electrode is not immersed in any liquid. Only air (or shielding gas) column exists in between the electrode and workpiece. | EDM electrode is commonly immersed in suitable dielectric fluid (kerosene, deionized water, hydrocarbon oil, etc.). However, appropriate gas can also be used as dielectric in dry-EDM. |

| Electrode wear rate is comparatively higher. Accordingly, electrode life is less, even with non-consumable electrode. | Electrode or tool wear rate is low, and thus tool life is more. |

| Welding electrodes mostly come in the form of rod or wire. | EDM electrodes can have wide variety of shapes including wire, flat dye, etc. |

| Usually welding electrodes are not given specific profile. | EDM electrodes must have specific profile in accordance with the desired feature shape, especially for dye sinking EDM. |

| Close tolerance and high dimensional accuracy are not desired in welding electrodes. | EDM electrodes require tight tolerance and high dimensional accuracy. |

| In few welding processes, the electrode is coated with appropriate flux. | EDM electrode is not coated with flux; however, insulation may be required in certain cases. |