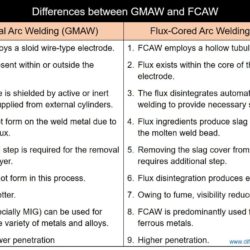

Difference Between GMAW and FCAW – Gas Metal Arc Welding and Flux-Cored Arc Welding

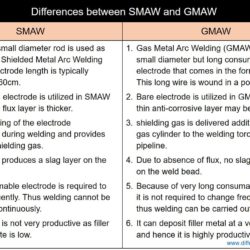

Arc welding is a sub-group of fusion welding where an electric arc is used to supply heat for fusing the parent metals for coalescence formation. The electric arc is constituted between an electrode and the base metals. The arc welding electrode can be either consumable or non-consumable. A consumable electrode is meant for melting by the arc heat, and subsequently depositing on the weld bead to supply filler metal. Such