Welding is one type of manufacturing process by which two or more similar or dissimilar materials can be joined permanently by weld bead formation with or without the application of external pressure, heat or filler material. There exist different types of welding processes, each of them follows unique procedure to weld two or more components. Welding processes can be broadly classified as arc welding, gas welding, resistance welding, solid state welding and intense energy beam welding. Each of these class once again consists of several welding processes. Irrespective of the welding process, a weld bead formation is always desired to join the components by welding. This weld bead forms at the intersection of two components that are welded. It is also worth mentioning that fusion of the faying surfaces of the parent components is not necessary for weld bead formation. In some welding processes, the faying surfaces are fused with the application of heat to get the weld bead, while in other processes, weld bead can be obtained without melting the faying surfaces. On the basis of whether base materials are fused or not, welding processes can be broadly classified into two groups—solid state welding and fusion welding.

In all such welding processes where the faying surfaces of parent components along with the filler material are fused to form the weld bead are called fusion welding. Sufficient heat must be applied by external means for properly fusing the faying surfaces of base metals as well as the filler metal. Thus phase change (solid to liquid and once again liquid to solid) occurs in fusion welding. All arc welding, gas welding, resistance welding and intense energy beam welding processes are fusion welding. On the other hand, if no such melting takes place during welding, then it is termed as solid state welding. Here the joining takes place in solid state and no phase change occurs. However, in solid state welding, parent components may be heated to an elevated temperature but substantially below the melting point of the concerned material (and thus no melting occurs). Instead of external heat, application of pressure is usually necessary for this type of welding. Roll welding, diffusion welding, friction welding, etc. are considered as solid state welding processes. Following passages elaborate similarities and differences between fusion welding and solid state welding.

Similarities between fusion welding and solid state welding

- Both fusion welding and solid state welding provide permanent joints. A permanent joint is one that does not allow dismantling of the assembled components without breaking them. All weld joints and rivet joints and most adhesive joints provide permanent joints.

- Coalescence or weld bead is formed in both the cases.

- Both can produce sound joint, if carried out properly.

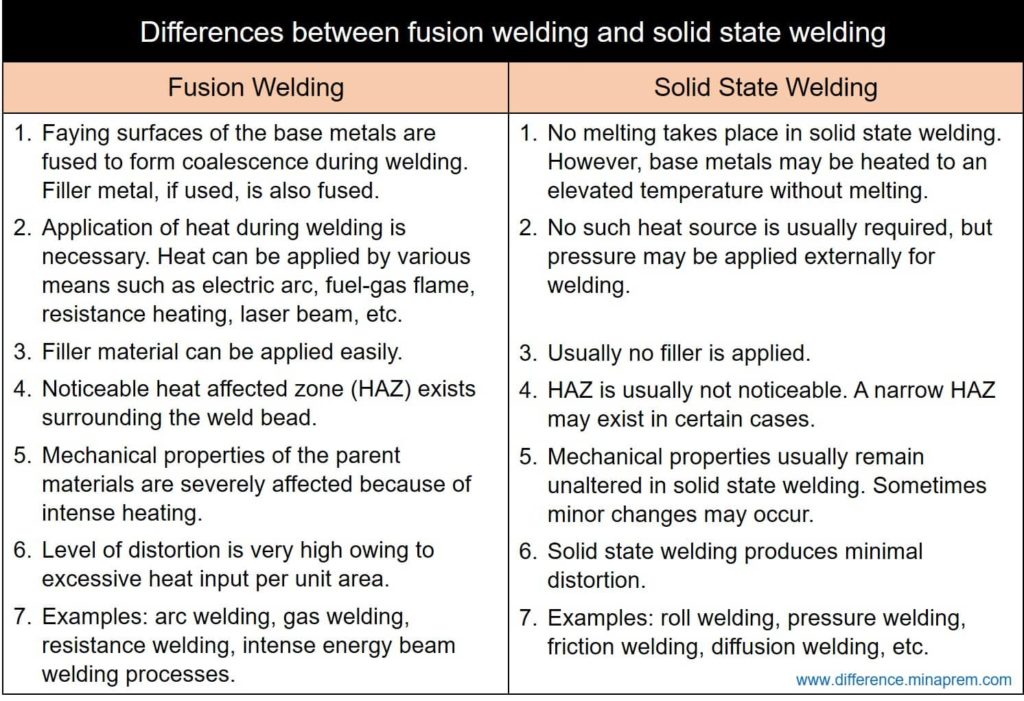

Differences between fusion welding and solid state welding

| Fusion Welding | Solid State Welding |

|---|---|

| Faying surfaces of the base metals are fused to form coalescence during welding. Filler metal, if used, is also fused. | No such melting takes place in solid state welding. However, the base metals may be heated to an elevated temperature without melting. |

| Application of heat during welding is necessary. Heat can be applied by various means such as electric arc, fuel-gas flame, resistance heating, laser beam, etc. | No such heat source is usually required, but pressure may be applied externally for welding. |

| Filler material can be applied easily. | Usually no filler is applied. |

| Because of excessive heating, noticeable heat affected zone (HAZ) exists surrounding the weld bead. | HAZ is usually not noticeable. A narrow HAZ may exist in certain cases. |

| Mechanical and metallurgical properties of the parent materials are severely affected during fusion welding because of intense heating. | Mechanical properties usually remain unaltered in solid state welding. Sometimes minor changes may occur. |

| Dissimilar metal joining by fusion welding is a challenging task, especially if the duo have substantially different melting points and coefficients of thermal expansion. | Joining of dissimilar metal is comparatively easier by solid state welding processes as melting and solidification are not involved here. |

| Level of distortion is very high in fusion welding owing to excessive heat input per unit area. | Solid state welding produces minimal distortion. |

| Joint design and edge preparation are not crucial. These parameters mainly influence achievable penetration. | Joint design, edge preparation and surface preparation are crucial here as the processes require specific mating surfaces. |

Examples of fusion welding processes:

|

Examples of solid state welding processes:

|

References

- Comprehensive Workshop Technology (Manufacturing Processes) by S. K. Garg (Laxmi Publications Private Limited).

- Design of Machine Elements by V. B. Bhandari (Tata McGraw Hill Education Private Limited).

- Welding Engineering: An Introduction by D. H. Phillips (Wiley).