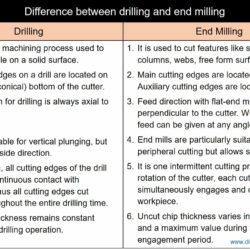

Difference Between Drill and End Mill – Drilling vs End Milling

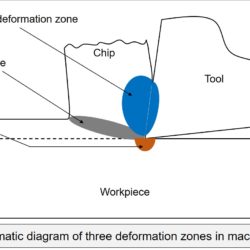

Machining is one type of manufacturing process where excess material is removed from the workpiece to impart intended shape, size and finish. It follows the principle of subtractive manufacturing approach to build 3-D components. Conventional machining processes employ a cutting tool that contain one or more shape edges, and layer by layer material is removed from the workpiece in the form of solid chips. In order to process a wide