There exist four basic non-traditional machining processes (EDM, LBM, EBM, and PAM) where thermal energy is utilized to melt and vaporize a tiny volume of material from the workpiece. Although mechanism of material removal is same in all four processes, the source of heat is different. In Electron Beam Machining (EBM), a concentrated beam of electrons is used as heat source. Here ample electrons are first generated using an electron gun, and then these are accelerated in an electric field under the presence of potential difference. High velocity electrons are then concentrated in the form a beam and the beam is directed towards the workpiece. When high velocity electrons strike the work surface, their kinetic energy gets converted into thermal energy and thus immense heat is generated. This increases localized temperature to as high as 10,000°C, which instantaneously melts down and vaporizes the material. To dislodge the striking electrons as well as to maintain electrical neutrality, the workpiece is grounded. Thus EBM process can be applied to electrically conductive materials only. Moreover, it requires a vacuum chamber to avoid collision of electrons with the air molecules.

Laser Beam Machining (LBM) process utilizes a coherent beam of laser (photons having same frequency, wavelength and phase) as the heat source for material removal purpose. LASER (light amplification by stimulated emission of radiation) is basically a coherent and amplified beam of electromagnetic radiation. Photon particles are first generated using a laser medium (such as Nd-YAG) with the assistance of excitation source (a flash tube). Ample photon particles are then concentrated and allowed to eject through a small opening in the form of a beam. This high energy density laser beam is then directed towards the workpiece surface. The thermal energy of the photon particles instantaneously melts down and vaporizes the workpiece material. It eliminates the material restriction imposed by EBM process based on conductivity. Thus LBM can be applied to a wide variety of materials (both conductive and non-conducive) as long as the surface is not highly reflective. Moreover, no vacuum chamber is required in LBM process. Various similarities and differences between EBM and LBM are given below in table format.

Similarities between EBM and LBM

- Both EBM and LBM are considered as thermal energy based non-traditional machining process.

- Mechanism of material removal (i.e. localized melting and vaporization) is same in both the processes.

- Both the processes utilize high intensity (i.e. high energy density) beam for material removal. However, the beam constituent is different.

- No physical contact between tool and workpiece exists in any of these processes. So the processes are free from burr and mechanically induced residual stress.

- Both the processes are affected by narrow heat affected zone (HAZ) and recast layer.

- For both the processes, the kerf width (actual width of the machined feature) is larger than the beam diameter.

- Wide variety of pulse modes and durations are also available in both the cases.

- Computer control system can be integrated with both the processes to facilitate precise control.

- In both the cases, beam intensity and cross-sectional area can be manipulated multifariously to harness desired performance.

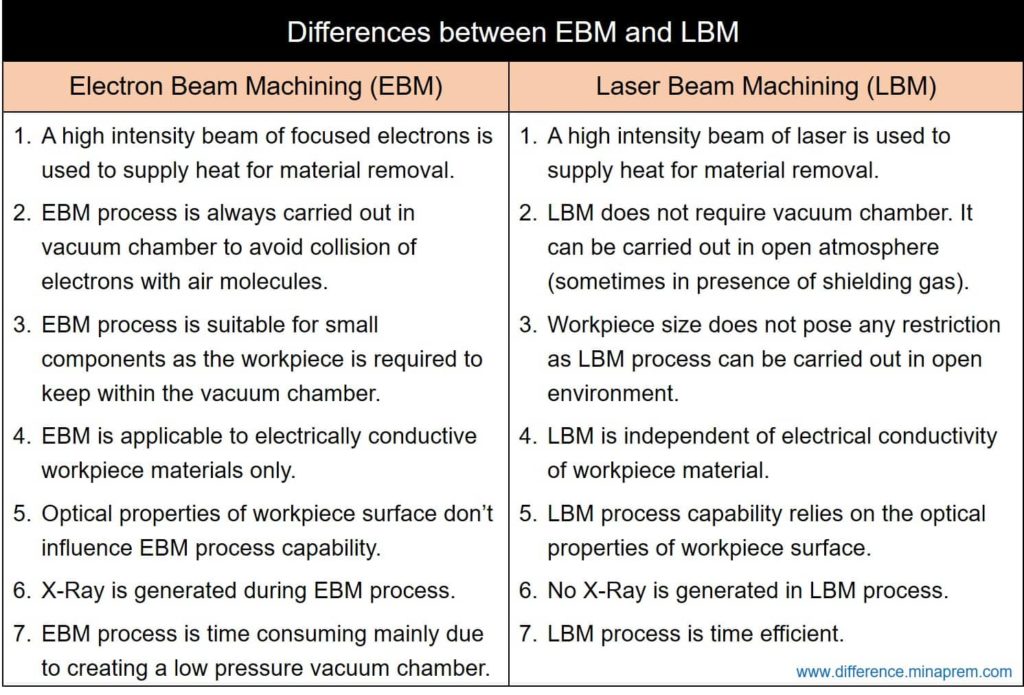

Differences between EBM and LBM

| Electron Beam Machining (EBM) | Laser Beam Machining (LBM) |

|---|---|

| A high intensity beam of focused electrons is used to supply heat for material removal. | A high intensity beam of laser (coherent photons) is used to supply heat for material removal. |

| EBM process is always carried out in vacuum (very low pressure) chamber to avoid collision of electrons with air molecules. Such collision can undesirably reduce kinetic energy of electrons and spread them. | LBM does not require vacuum chamber. It can be carried out in open atmosphere. Sometimes shielding gas can be applied in machining zone to avoid high temperature oxidation of machined surface. |

| It is suitable for small components as workpiece is required to keep within the vacuum chamber. | Workpiece size does not pose any restriction as it can be carried out in open environment. |

| EBM process is time consuming mainly due to creating a low pressure vacuum chamber. | LBM process is time efficient. |

| X-Ray is generated during EBM process. This possesses serious health concern to the operator. | No X-Ray is generated in LBM process. |

| EBM is applicable to electrically conductive workpiece materials only as workpiece must be grounded to stay neutral by transmitting striking electrons to the ground. | LBM is independent of electrical conductivity of workpiece material. So it can be used for both conductive and non-conductive materials. |

| Optical properties of workpiece surface (such as reflectivity, absorptivity, etc.) don’t influence EBM process capability. | LBM process capability relies on the optical properties of workpiece surface. High reflectivity can severely affect process capability. |

References

- Unconventional Machining Processes by T. Jagadeesha (I. K. International Publishing House Pvt. Ltd.).

- Nonconventional Machining by P. K. Mishra (Narosa Publishing House).

- Dubey et al. (2008), Laser beam machining—A review, International Journal of Machine Tools and Manufacture, 48, 609-628. https://doi.org/10.1016/j.ijmachtools.2007.10.017