In manufacturing industries, joining of two or more components is indispensably necessary for assembly purposes. Joining makes the production system more reliable, efficient and profitable. In fact, joining can be defined as one of the manufacturing processes by which two or more solid components can be assembled together with or without the application of external elements such as filler, strap, heat, pressure, etc. There exist various joining techniques in order to assemble a larger variety of materials in innumerable ways. Some of these methods can join components permanently, while others can join temporarily. Accordingly, joining can be classified into two groups— temporary and permanent.

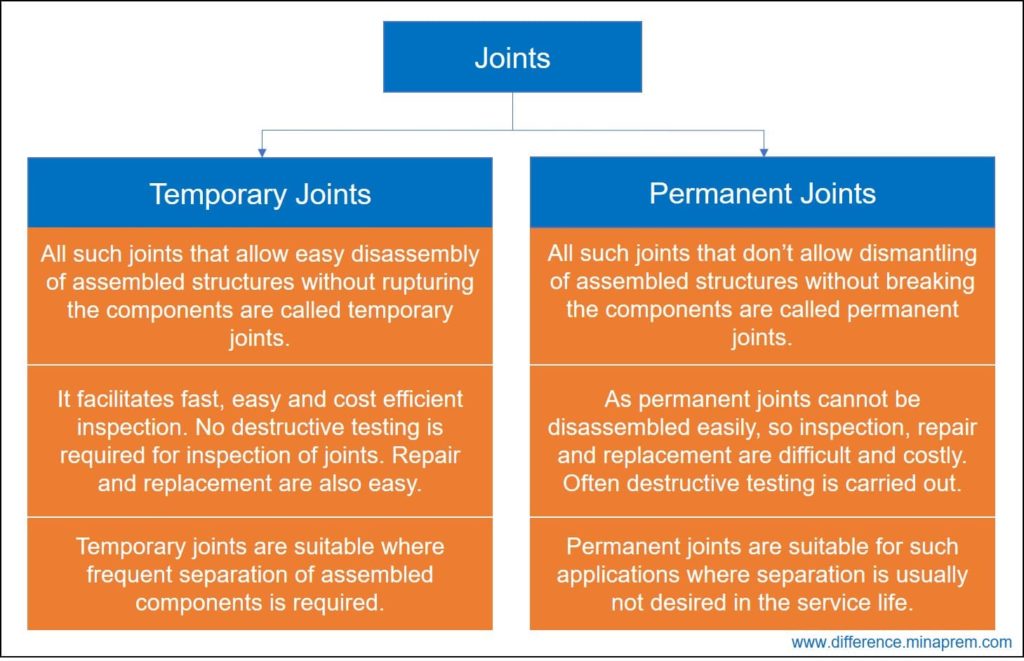

A permanent joint does not allow dismantling of joined parts without breaking them. As the name suggests, these joints are permanent in nature and usually offer a sound and leak-proof joining. Welding is the fast and foremost example for this category. Apart from welding, rivet joint, soldering, brazing, many adhesive bonding, etc. are also permanent joints. A temporary joint allows disassembly of assembled structures without rupturing the components. Easy disassembly makes inspection and maintenance very easy. However, strength of the temporary joints may not be as high as in a permanent joint. Various differences between temporary joints and permanent joints are given below in table form.

Differences between temporary joint and permanent joint

| Temporary Joint | Permanent Joint |

|---|---|

| Temporary joints allow easy dismantling of assembled components without breaking them. | Permanent joints don’t allow dismantling of assembled components without rupturing them. |

| Temporary joints are not necessarily leak-proof. | Permanent joints are usually leak-proof. |

| Strength of temporary joint is comparatively less. | Strength of permanent joint is high. Usually joint strength is same with that of the components. |

| It facilitates fast, easy and cost efficient inspection. No destructive testing is required for inspection of joints. | As permanent joints cannot be disassembled easily, so inspection is difficult and costly. Often destructive testing is carried out, which damages the assembled structures. |

| Repair and replacement are also easy. | Repair and replacement are difficult and costly. |

| Temporary joints are suitable where frequent separation of assembled components is required. | Permanent joints are suitable for such applications where separation is usually not desired in the service life. |

Examples of various temporary joints:

|

Examples of various permanent joints:

|

References

- Introduction to Machine Design by V. B. Bhandari (McGraw Hill Education India Private Limited).

- A Textbook of Machine Design by R. S. Khurmi and J. K. Gupta (S. Chand).

- Theory of Machines by R. S. Khurmi and J. K. Gupta (S. Chand).