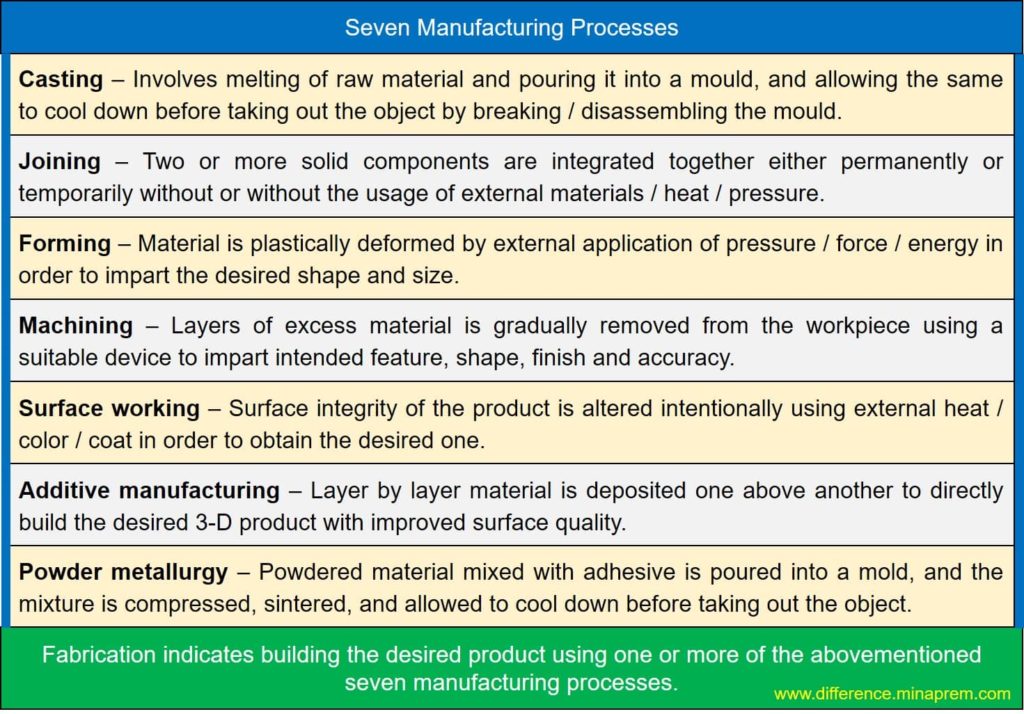

Fabrication indicates building the desired component using one or more manufacturing processes. Manufacturing is one technical term that is defined as a step by which raw material or scrap is converted to the useful product by adding substantial values. The manufacturing step consists of seven basic processes – each of these processes once again consists of many operations. Machining is just one manufacturing process; there are many others as discussed below.

1. Casting is one manufacturing process: The oldest manufacturing process where the raw material is first melted, poured into a pre-built mould and subsequently allowed to cool down. This mould is built in accordance with the desired object as the inverse profile of the mould is imparted on the object. Once solidified, the object inside the mould is taken out by breaking (or disassembling) the mould. There are several casting operations (like sand casting, permanent mould casting, investment casting, centrifugal casting, etc.), each one has unique benefits and limitations and thus is suitable for particular applications. Whatever be the case, casting process is suitable to provide a basic shape and size to the product, but mostly it cannot provide complex shapes, intricate details and smooth surfaces in mass production. Therefore, casting is one basic manufacturing process that can impart basic form to the object.

2. Joining is one manufacturing process: Joining is another manufacturing process by which two or more materials can be integrated temporarily or permanently to get a single larger unit. As usual there are various joining processes such as welding, soldering, brazing, riveting, fastening, coupling, adhesives, etc. to facilitate joining of wide variety of materials in innumerable ways.

3. Forming is one manufacturing process: In forming, work material is plastically deformed by external application of pressure (or force). The deformation is carried out in accordance with the desired product, its features and dimensions. Various forming operations include rolling, forging, extrusion, drawing, etc.

4. Machining is one manufacturing process: Machining is one secondary manufacturing process where excess material is gradually removed from the workpiece in order to impart desired shape, size and finish. There are various types of machining processes including conventional machining (like turning, milling, drilling, facing, etc.), non-traditional machining (like AJM, USM, EDM, ECM, CHM, LBM, etc.), abrasive cutting (like grinding, lapping, honing, etc.) and micro-machining (like micro-milling, precision turning, micro-drilling, etc.). However, every machining process follow the same basic principle of gradual removal of excess material from workpiece (this machining is one subtractive manufacturing process).

5. Surface working is one manufacturing process: It is also one secondary manufacturing process where surface integrity of the product is altered to obtain the desired one. Usually it does not change the shape or dimension of the component; however, various surface properties are altered. Thus surface working is also known as surface modification. It include several operations including heat treatment, coating, colouring, etc.

6. Additive manufacturing is one manufacturing process: Contrary to the subtractive manufacturing (or machining) process where layer by layer material is gradually removed from the solid 3-D workpiece, in additive manufacturing, layer by layer material is deposited one above another to build a 3-D product. Even though the manufacturing approaches are opposite in these two cases, the ultimate product may be same. This additive manufacturing process include several operations like 3-D printing, rapid prototyping, lithography, etc.

7. Powder metallurgy is another manufacturing process: It is also one manufacturing process where fine-grain (or powdered) material is poured into a mould after mixing with appropriate adhesive. The mixture is then compressed, sintered without melting, and subsequently allowed to cool down. A solid 3-D component with intricate details can be built by this process; however, it is suitable for small size objects. It is similar to casting to some extent, but here no melting takes place (although powder and adhesive mixture is heated to an elevated temperature).

What is the difference between machining and fabrication?

Fabrication is nothing but making or producing desired product using appropriate raw material. One or more of the above mentioned seven manufacturing processes are utilized to fabricate the intended product. So fabrication is carried out with the assistance of one or more manufacturing processes. Machining is just one among seven types of manufacturing processes. Therefore, machining is one gradual material removal process that may or may not be required for fabrication of a product.