Joining is a part and parcel in manufacturing as it is used to assemble two or more solid components either permanently or temporarily. Although a permanent joint does not allow disassembly of parts without rupturing them, it has immense demand in assembly as it can provide a strong, leak-proof and inherently anti-loose joint. Welded joint and riveted joint are two commonly used permanent joining processes; however, now-a-days riveted joints are mostly superseded by various advanced welding processes. By definition, welding is one type of joining process where two or more materials can be joined permanently with or without the application of external heat, pressure and additional material. There exists a wide variety of welding processes that can join various materials in innumerable ways. Welding can be used to join metals, ceramics and polymers in several fashions like lap joint, butt joint, T-joint, etc. Strength of the weld joint is very high as it does not require any holes to be drilled on the component. Moreover, it is one continuous type joint and thus offers a leak-proof joining.

A rivet joint is also one type of permanent joint; however, it mandatorily requires a series of holes on the components. Prior to riveting, arrays of through holes are first drilled on the components (and also in strap plates, if used). Rivets of specific dimensions are then inserted within such holes. The protruded end of the rivet shank is hammered (upsetting) to make another closing end opposite to the rivet head. Sometimes rivet shank is heated to an elevated temperature prior to upsetting in order to reduce upsetting pressure requirement. In riveting, two or more components are held together by means of tensile stress developed within the rivets. However, due to the presence of holes in the components (this reduces the effective cross-sectional area), the load carrying capacity of the assembled structure reduces significantly. Unlike welding that gives a continuous joint, riveting provides an intermittent joint and thus it is associated with the risk of leakage, especially at high pressure fluid applications. Various similarities and differences between weld joint and rivet joint are discussed in the following sections.

Similarities between weld joint and rivet joint

- Both welding and riveting are mechanical joining processes as no chemical reaction occurs during joining. This is unlike the adhesive joining technique where chemical reaction takes place.

- Both are permanent joints and thus welded or riveted components cannot be disassembled without breaking them. Apart from welding and riveting, coupling, adhesive joining, etc. are also permanent joints. On the contrary, fastening, cotter joints, press fit, etc. are considered as temporary joints.

- Both can be applied for joining of two or more components together.

- Both can provide significantly strong and sound joint.

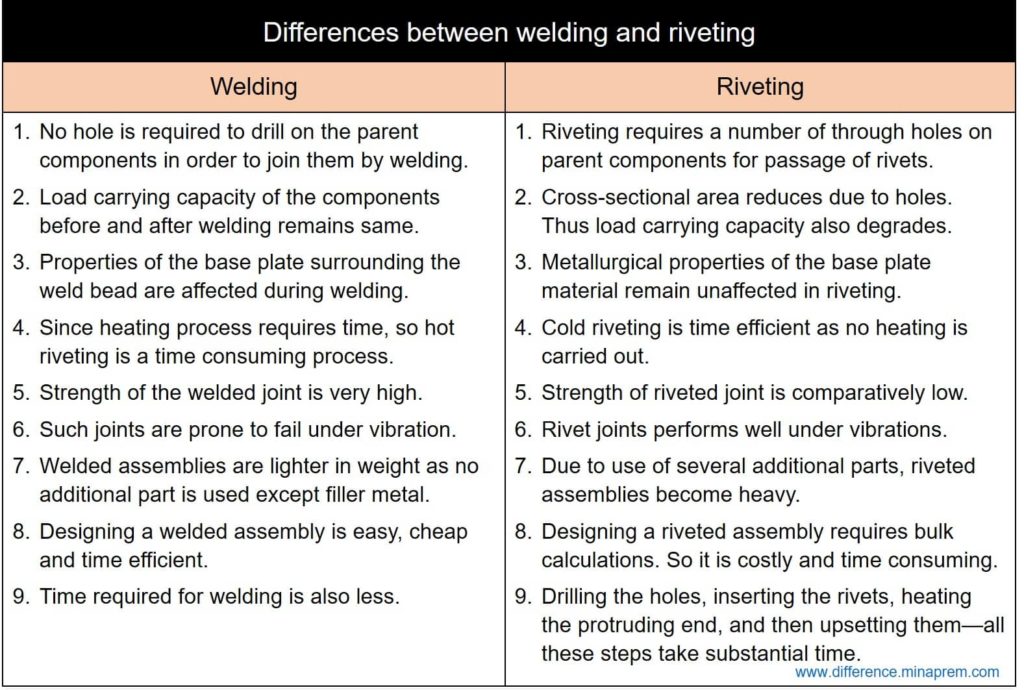

Differences between weld joint and rivet joint

| Weld Joint | Rivet Joint |

|---|---|

| No hole is required to drill on the parent components in order to join them by welding. | Riveting require a number of through holes in specific locations on the parent components for the passage of rivets. |

| Load carrying capacity of the parent components before and after welding remains more or less same. | Due to presence of holes on the parent components, effective cross-sectional area reduces, and thus load carrying capacity also degrades after riveting. |

| Many welding processes (fusion welding mainly) tend to change metallurgical properties of the base plate surrounding the weld bead. | Metallurgical properties of the base plate material remain unaffected in riveting. |

| Strength of the welded joint is very high; often it is more than the strength of base plates (i.e. welding joint strength is 100%). | Strength of riveted joint is comparatively low. |

| Most welding processes give a continuous type joint (except resistance welding process). | Riveting is inherently an intermittent type joint as small gap exists between two adjacent rivets. |

| Welded assemblies are prone to fail under vibration. With the advancement of welding technology, now welded structures remain stable under vibrations. | Rivet joints performs well under vibrations (this is the reason behind the popularity of riveting in bridge construction in early days). |

| Weld joints are usually leak proof. | Rivet joints may not offer leak proof joints, particularly in high pressure applications (e.g. super-critical broiler). |

| Welding requires no additional plates or straps, except the filler material in some cases. | Riveting requires additional cover plates, straps as well as multiple rivets. |

| Welded assemblies are lighter in weight. | Due to use of several additional parts, riveted assemblies become heavy. |

| Designing a welded assembly is easy, cheap and time efficient. | Designing a riveted assembly requires a substantial amount of calculations, and thus it is costly and time consuming. |

| Time required for welding is also less. | Drilling the holes, inserting the rivets, heating the protruding end, and then upsetting them—all these steps take substantial time. |

| Appearance of welded assembly is good. The reinforced part of the weld bead and spatters can be removed easily by grinding to improve appearance. | Rivet head and the closing head always remain protruded from the surface. This hampers the appearance of riveted assemblies. |

| Various shapes such as circular or elliptical shafts can be easily joined by welding. | Such shapes cannot be joined by riveting without using additional plates. |

| Welding can be applied for joining of metals as well as ceramic, plastic and also composites. | Riveting is useful only for joining of metals. |

| Welded joints have a wide variety of applications where a permanent joining is desired. Examples include, but not limited to, pipe or rod joining, sheets or plates joining, automobile industries, joining of railway tracks, common civil applications, etc. | Although now-a-days rivet joints are mostly superseded by weld joints, the former one were used in:

|

References

- Design of Machine Elements by V. B. Bhandari (Tata McGraw Hill Education Private Limited).

- Analysis and Design of Machine Elements by V. K. Jadon and S. Verma (I. K. International Publishing House Private Limited).

- Fundamentals of Machine Drawing by S. Singh and P. L. Sah (PHI Learning Private Limited).