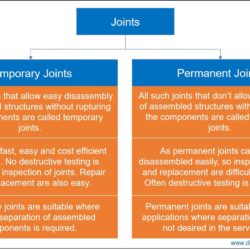

Difference Between Temporary Joining and Permanent Joining

In manufacturing industries, joining of two or more components is indispensably necessary for assembly purposes. Joining makes the production system more reliable, efficient and profitable. In fact, joining can be defined as one of the manufacturing processes by which two or more solid components can be assembled together with or without the application of external elements such as filler, strap, heat, pressure, etc. There exist various joining techniques in order