Several advanced machining processes have been developed over the last few decades to cater the evergrowing demand of high quality small-scale products made of a wide variety materials with highly finished surfaces and close tolerance. Laser beam machining and ion beam machining are two such processes that follow subtractive manufacturing approach to fabricate intended features with improved accuracy and tight tolerance. However, their working principle and extent of capability are different. Laser Beam Machining (LBM) is one thermal energy based non-traditional machining process where a concentrated and coherent beam of photons (laser) is used to supply thermal energy (heat) for selectively removing material from the workpiece. When the laser beam strikes the workpiece, intense heat generation takes place in a narrow localized zone that can cause an instantaneous temperature rise of the order of 10,000°C. Such a high temperature can virtually melt and vaporize any solid material. Accordingly, the material is mostly removed in the form of vapour of the concerned workpiece material. The LBM process does not require a vacuum chamber for its operation. Though LBM offers relatively high material removal rate, it leads to the formation of a narrow heat-affected zone (HAZ). The process is also affected by re-cast layer formation and taper cutting while machining thick samples.

Ion Beam Machining (IBM) is another non-traditional machining process, but here material removal occurs due to mechanical impact. Unlike LBM, here thermal energy (heat) has no direct role in removing material. In IBM, a concentrated beam of high velocity ions is allowed to strike the workpiece surface. Upon striking, momentum transfer takes place between the incidental ions and the atoms of the workpiece surface. This results in dislodging of atoms from the surface leading to material removal. Thus material removal occurs in atomic level without any melting or vaporization. Although IBM offers very low material removal rate (MRR), it generates highly finished surface with nanometric level roughness. In fact, a variant of IBM known as Focused Ion Beam (FIB) is preferred for micro- or nano-fabrication and surface smoothing. Furthermore, the process is free from collateral thermal damages and re-cast layer formation. However, the IBM process must be carried out in a soft vacuum chamber to avoid haphazard collision between the ions and air molecules. Creating vacuum chamber is time consuming, which makes the overall process less productive. Various similarities and differences between LBM and IBM processes are given below in table format.

Similarities between LBM and IBM

- Both laser beam and ion beam machining processes are considered as non-conventional machining processes (NTM) or advanced machining processes (AMP).

- In none of the processes, there exists physical contact between a solid tool and the workpiece. So these processes are free from burr formation, residual stress generation, negative influences of gradual wear, etc. Note that, residual stress generation may occur in LBM owing to thermal cycle.

- Both the processes are independent of electrical, chemical, and mechanical properties of the workpiece material. So these processes can be applied on a wide variety of materials.

- These processes are expensive, and thus are used for sophisticated works only.

- These processes are commonly integrated with computer control system to facilitate precise control.

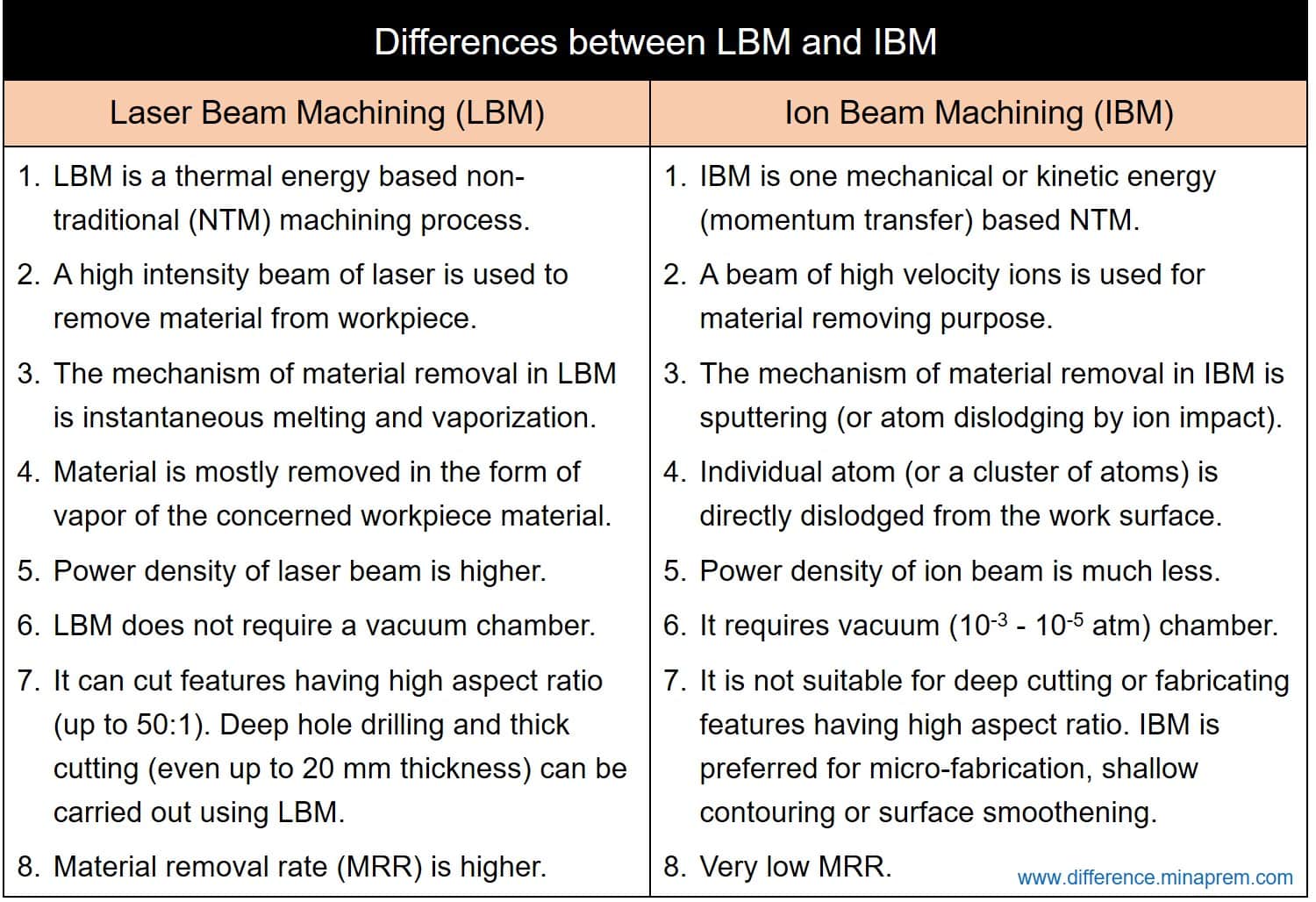

Differences between LBM and IBM

| Laser Beam Machining (LBM) | Ion Beam Machining (IBM) |

|---|---|

| LBM is a thermal energy based non-traditional machining process. | IBM is essentially a mechanical or kinetic energy (momentum transfer) based non-traditional machining process. |

| A high intensity beam of laser (coherent photons) is used to remove material from workpiece. | A beam of high velocity ions are used to remove material from workpiece. |

| The mechanism of material removal in LBM is instantaneous melting and vaporization. | The mechanism of material removal in IBM is sputtering (or atom dislodging by ion impact). |

| In LBM, material is removed in the form of vapour of the concerned workpiece material. However, a small fraction of material is removed in molten state. | In IBM, individual atom (or a cluster of atoms) is removed or dislodged directly from the workpiece surface without any melting or vaporizing. |

| Power density of the laser beam is relatively higher (104 to 106 W/mm2). | Power density of the ion beam is significantly less (10-2 to 100 W/mm2). |

| LBM does not necessarily require a vacuum chamber. It can be carried out in open atmosphere. Sometimes shielding gas can be applied in machining zone to avoid high temperature oxidation of the machined surface. | IBM process is carried out in a soft vacuum chamber having pressure in the order of 10-3 to 10-5 atm. |

| Applicability of LBM process depends on the optical properties (reflectivity, absorptivity and transmittivity) of the workpiece surface. | IBM process is independent of optical properties of the workpiece surface. |

| Process capability and productivity depend on thermal properties (such as conductivity, diffusivity, etc.) of the workpiece material. | It is mostly independent of the thermal properties of the workpiece material. |

| It can cut features having high aspect ratio (up to 50:1). Deep hole drilling and thick cutting (even up to 20 mm thickness) can be carried out using LBM. | It is not suitable for deep cutting or fabricating features having high aspect ratio. IBM is preferred for micro-fabrication, shallow contouring or surface smoothening. |

| LBM process is affected by re-cast layer formation, especially during cutting thick specimens. | No such re-cast layer formation occurs in IBM. |

| The area of thermal damage on the workpiece is relatively larger in LBM process. | Impact damage on the workpiece is very narrow in IBM process. Often, no palpable collateral damage is noticed. |

| Material removal rate (MRR) of LBM process is significantly higher (5 – 50 mm3/min). So it is a productive and economic process. | Material removal rate (MRR) of IBM process is very low (in the order of 2 × 10-4 mm3/min). |

References

- Unconventional Machining Processes by T. Jagadeesha (I. K. International Publishing House Pvt. Ltd.).

- Nonconventional Machining by P. K. Mishra (Narosa Publishing House).

- Allen et al. (2009). Ion beam, focused ion beam, and plasma discharge machining. CIRP Annals. https://doi.org/10.1016/j.cirp.2009.09.007