Primary objective of any subtractive manufacturing process is to remove layer by layer material from a solid 3-D blank to achieve desired shape, size and finish. Achieving high dimensional accuracy, close tolerance and surface finish are usually not possible by conventional machining processes like turning, milling, shaping, planing, drilling, etc. Such processes are mainly applied for bulk removal (stock removal) of material with high material removal rate. In order to improve surface quality and dimensional accuracy, separate finishing operations can be carried out. Grinding, reaming, honing, lapping, etc. are classified as surface finishing processes. Such processes offer low material removal rate (MRR) but high accuracy, close tolerance and better finish.

Conventional machining (also known as metal cutting) processes utilize a sharp-edged wedge shaped cutting tool to compress and shear off material from workpiece. This cutting tool has defined geometry. Cutter material also varies widely – from age old carbon steel to modern day’s materials like cBN and diamond. On the other hand, grinding utilizes a circular wheel made of sharp, tiny and random shaped abrasive grits strongly held on suitable bonding medium. These abrasives actually remove material from work surface in the form of micro-chips to provide a smooth surface. Although grinding wheel has defined specification, the abrasive grits have no specific geometry. Moreover, only a limited types of abrasive is used, like alumina, silica, diamond, etc. Important similarities and differences between machining and grinding are discussed below.

Similarities between machining and grinding

- Both machining and grinding processes follow the basic principle of subtractive manufacturing approach. Here layers of excess material are removed from a solid 3-D blank to obtain final product. On the contrary, in additive manufacturing approach, layer by layer material is added one over another to build a solid 3-D product.

- In both the machining and grinding processes, material removal takes place in the form of solid chips.

- In both the cases material is removed by shearing (ploughing and rubbing occur in grinding but they do not remove material).

- Presence of cutter is mandatory in both the cases for realizing material removal.

- Only mechanical energy is utilized for material removal in both the cases (unlike NTM processes where various forms of energy like mechanical, electrical, thermal, chemical, etc. are used to remove material).

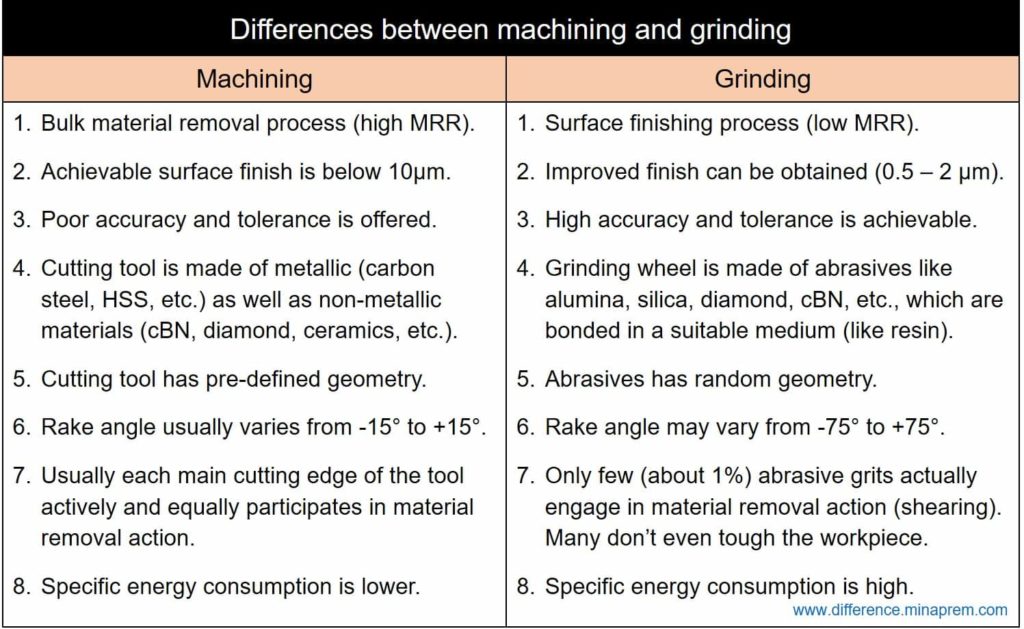

Differences between machining and grinding

| Machining | Grinding |

|---|---|

| Machining is one bulk material removal process (i.e. high MRR). Thus it is economical and suitable to give proper size and also for semi-finishing. | Grinding has low material removal rate and is preferred only for finishing. |

| Accuracy and tolerance achieved by conventional machining operations are not so good. Achieving tolerance below 50µm is very difficult. | It can provide better accuracy and tolerance. In grinding, achievable tolerance can be as low as 2µm. |

| In machining, cutting tool is usually made of metals or alloys, which is substantially harder than work material. However, ceramic, diamond and cBN tools (non-metallic) are also available, usually in the form of inserts. | Cutting tool for grinding, i.e. the wheel, is made of abrasive materials (such as alumina, silica, etc.) bonded in harder medium (like resin, metal, etc.). |

| Cutting tool used in machining has specific geometry. Values of the geometrical features may vary from one tool to another, but each tool has pre-defined geometry as per tool signature. | Grinding wheel may have specific pre-defined features, but the abrasive grits (which actually participate in material removal) have random geometry and orientation. |

| Rake angle of a cutting tool may vary from positive to negative. However, the negative rake usually does not go above (–15º) as it may severely degrade machinability. | Abrasive grits have haphazard rake angle. A much wider variation of rake angle from (+75º) to (–75º) is noticed among abrasive grits. |

| During machining operation, each main cutting edge of the tool actively and mostly equally participates in material removal action. | Only few (about 1%) abrasive grits actually engage in material removal action (shearing). Some grits just engage in rubbing, scratching and ploughing. A major percentage of grits do not even touch the work material in every rotation. |

| Generated cutting temperature is comparatively low, and only a tiny portion (5-8%) of it diffuses into the workpiece. Thus thermal damage of the machined surface is usually insignificant. | Severe heat is generated during grinding, and also a substantial amount of heat diffuses into the workpiece. This causes thermal damage of the machined (ground) surface such as changing hardness. |

| The maximum cutting speed (rpm) used in conventional machining is typically limited to 2000 rpm (limited by the capability of machine tool, especially gears and bearings). Thus cutting velocity (m/min) is also lower. | Rotational speed of grinding wheel is much higher (2000 – 4000 rpm). Ultra high speed grinding (speed around 20,000 rpm) is also carried out for some specific applications. |

| Specific energy consumption (power per unit volume of material removed in kW/mm3) is much lower. | Specific energy consumption is 5–50 times higher than that of the machining. |

| There exist some surface hardened and inherently hard materials that cannot be machined by conventional methods. | Such materials can be finished by grinding without appreciable problem. |

References

- Machining and Machine Tools by A. B. Chattopadhyay (Wiley).

- Metal Cutting: Theory And Practice by A. Bhattacharya (New Central Book Agency).

- Manufacturing Process for Engineering Materials by S. Kalpakjain and S. Schmid (Pearson Education India).

- DeGarmo’s Materials and Processes in Manufacturing by J. T. Black and R. A. Kohser (Wiley).