In conventional machining, the cutting tool compresses a layer of work material to shear it off in the form of chips. Both the cutting tool and the workpiece is rigidly mounted on the machine tool maintaining appropriate orientation. All relative motions are also offered by the machine tool to smoothly accomplish material removal. In mass production of a product in conventional machine tool, same work is required to perform repeatedly for a large number of times. Several special purpose devices can be utilized in such scenario for easy, efficient, uninterrupted and productive machining. Jig and fixture are two special purpose devices that assist economic mass production requiring no additional set-up. They are meant for improving productivity, reducing human effort, reducing error due to human endurance, facilitating interchangeability, and minimizing rejection.

A jig is one special purpose device used to guide and locate the cutting tool to pre-defined position on the workpiece. Apart from guiding the cutter, it mandatorily holds, supports and locates the workpiece with respect to machine and cutter. Jigs are normally used in frilling, reaming and tapping. Basic purpose of a fixture is to securely mount the workpiece in correct position maintaining desired orientation with respect to machine and cutter. However, it cannot guide the cutting tool to move at a pre-defined location. Fixtures are commonly clamped to the machine tool and are used in reciprocating type operations like milling, shaping, slotting, planing, etc. It is to be noted that neither the jig nor the fixture is an integral part of machine. They are separate units that can be placed and temporarily clamped on the workpiece. Now-a-days, with the advent of automated or CNC (Computer Numerical Control) based machine tools, usage of such special purpose devices reduces considerably. Various similarities and differences between jig and fixture are given below.

Similarities between jig and fixture

- Jig and fixture mandatorily consist of arrangements for locating and clamping and an optional arrangement for tool guiding (jig bush).

- Both can eliminate individual marking and positioning. This reduces idle time during machining that ultimately improves productivity.

- Both tends to reduce unpredictive human error caused by performing similar task repeatedly for large duration (human too has an endurance limit or stress).

- Both can improve accuracy in machining in several ways. Thus close tolerance can be achieved easily. They also reduce production of defected items and thus rejection.

- Both are used for non-automatic machines. They are not necessary for automated CNC based machines as locating task is executed by pneumatic or hydraulic system.

- Both can partially automates the machining process (reduces human engagement in manufacturing).

- Both can be made of similar metals, such as phosphor bronze (reduces wear during repeated usage), high carbon steel, etc.

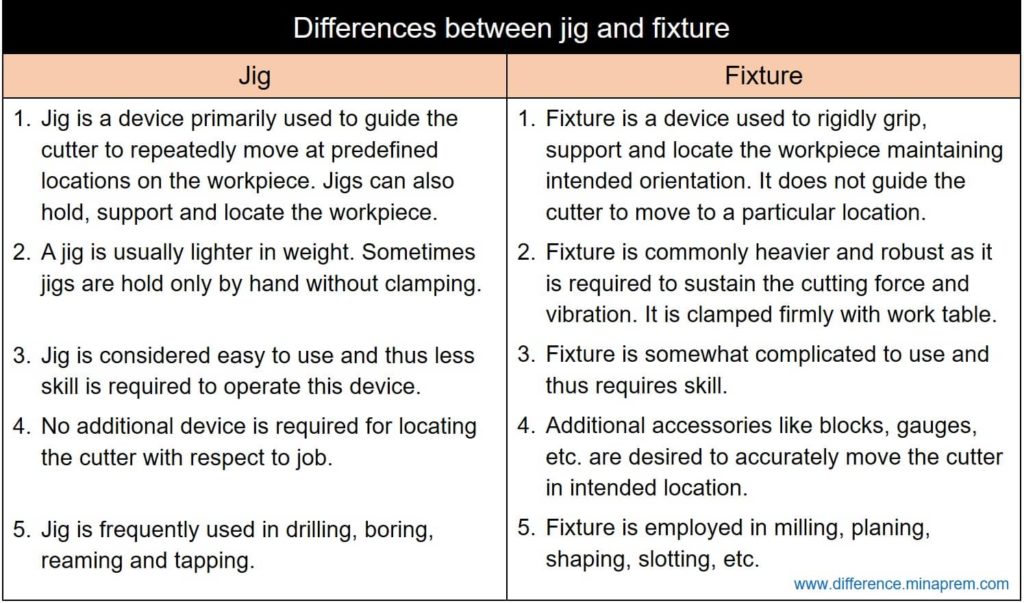

Differences between jig and fixture

| Jig | Fixture |

|---|---|

| Jig is a device primarily used to guide the cutter to repeatedly move at predefined locations on the workpiece. Jigs can also hold, support and locate the workpiece apart from guiding the cutter. | Fixture is a device used to rigidly grip, support and locate the workpiece maintaining intended orientation. It does not guide the cutter to move to a particular location. |

| A jig is usually lighter in weight. Sometimes jigs are hold by hand only without clamping. | Fixture is commonly heavier and robust as it is required to sustain the cutting force and vibration. So it is clamped firmly with the work table. |

| Jig is considered easy to use and thus less skill is required to operate this device. | Fixture is somewhat complicated to use and thus requires skill. |

| No additional device is required for locating the cutter with respect to job. | Additional accessories like blocks, gauges, etc. are desired to accurately move the cutter in intended location. |

| Jig is frequently used in drilling, boring, reaming and tapping. | Fixture is employed in milling, planing, shaping, slotting, etc. |

References

- Manufacturing Processes by J. P. Kaushish (PHI Learning Private Limited).

- Jigs and Fixtures by P. H. Joshi (Tata McGraw-Hill Publishing Company Limited).

- Manufacturing Processes–II by H. S. Bawa (Tata McGraw-Hill Publishing Company Limited).