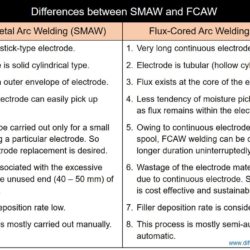

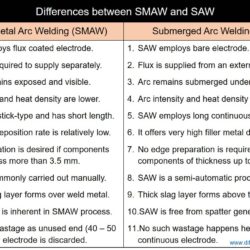

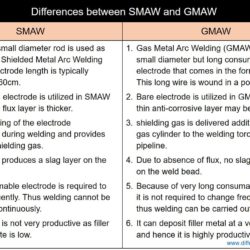

Difference Between SMAW and FCAW – Shielded Metal Arc Welding and Flux-Cored Arc Welding

A sub-group of fusion welding where electric arc is used to supply necessary heat for melting the faying surfaces of the base metals is termed as arc welding. Here the electric arc is established between an electrode and the base metals when sufficient potential difference is applied across them. For few arc welding processes, the electrode is allowed to melt and subsequently deposit on the weld bead to supply filler