Majority of mechanical machine units are driven by a prime mover, which converts mainly electrical energy into mechanical energy (usually in the form of rotation of a shaft). Power generated by the prime mover is transferred to the intended location for driving various elements of the machinery. Several power transmitting elements are used for such transmission purposes; each of them has specific advantages and disadvantages. Gear drive, belt drive, chain drive, rope drive, clutch, etc. are notable elements of mechanical power transmission system. Belt drive is one flexible drive where an endless belt (jointed or jointless) is employed to transmit power from driver shaft and driven shaft by means of friction between the belt and pulleys. It is simpler and economic as compared to gear drive or chain drive and can be used for medium to long shaft distances. It is also capable protecting the driver unit by absorbing vibrations. By means of slip, it can also keep the system safe from overloading.

Commercial belts are available in different cross-sections; among them flat belts and V-belts are frequently used. A flat bet has rectangular cross-section where width is significantly larger than thickness. It usages a cylindrical pulley where bottom surface of the belt comes in contact with the outer surface of the pulley. On the other hand, V-belt has trapezoidal cross-section with width comparable to height. It employs a pulley having corresponding V-grove to accommodate the V-belt. Both the side surfaces of the belt remains in contact with the pulley. Whereas flat belt is a jointed belt, V-belt is jointless. Although power transmission capability of flat belt is comparatively low, it can transmit power and motion to a longer distance. V-belt tends to eliminate slip but is costly and cannot be used for very long center distances. Various similarities and differences between flat belt and V-belt are given below in table format.

Similarities between flat belt drive and V-belt drive

- Both flat belt and V-belt drives can transmit power and motion to a longer distance as compared to gear drive.

- Both are suitable for transmitting power between parallel shafts only. Although little parallelism error does not possess any palpable problem, they are primarily not suitable for intersection shafts.

- Both of them are flexible drives due to the presence of flexible element (belt). A flexible drive can isolate the prime mover from machine unit and thus restricts transmission of undesired vibrations.

- Both are friction drives, which indicates power and motion are transferred from driver to driven shaft by means of friction between the pulley and belt.

- Although V-belt drive eliminates slippage, both of them are categorized under non-positive drive because of creep motion. In fact, V-belt can also slip when load on driven shaft exceeds a certain limit.

- Pulleys are indispensably required on both the shafts in every belt drive. However, pulley geometry varies based on belt configuration.

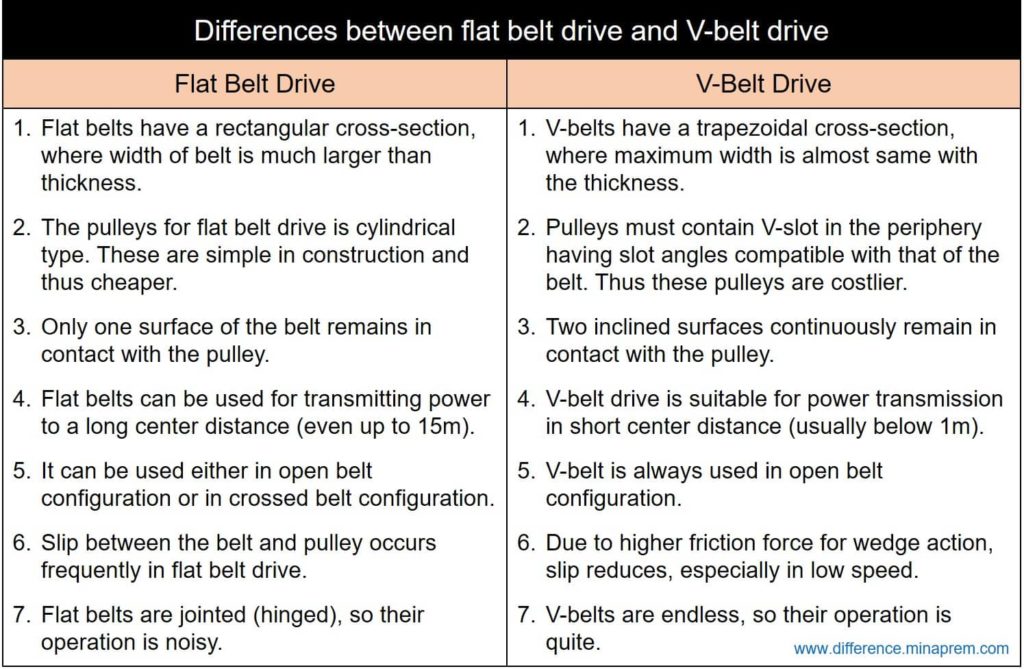

Differences between flat belt drive and V-belt drive

| Flat Belt Drive | V-Belt Drive |

|---|---|

| Flat belts have a rectangular cross-section, where width of belt is much larger than thickness. | V-belts have a trapezoidal cross-section, where maximum width is almost same with the thickness. |

| The pulleys for flat belt drive are simple in construction and thus cheaper. | Here pulleys must contain V-slot to accommodate V-belts. Slot angles must match with that of the belt, otherwise power transmission capability will reduce. Thus these pulleys are costlier. |

| In flat belt drive, only one surface of the belt remains in contact with the pulley. | In case of V-belt drive, two inclined surfaces continuously remain in contact with the pulley. |

| Wide range of velocity ratio can be obtained by utilizing stepped pulleys of different diameters and easily shifting belt from one pulley to another. | Such shifting provision does not exist in V-belt drive. |

| Flat belts can be used for transmitting power to a long center distance (even up to 15m). | V-belt drive is suitable for power transmission in short center distance (usually below 1m). |

| Flat belt drive can be used either in open configuration or in crossed configuration. | V-belt is always used in open configuration. |

| Efficiency of the flat belt drive is comparatively higher. | Efficiency of the V-belt drive is low. |

| Power transmitting capability of flat belt drive is low. | V-belt drive can transmit comparatively higher power because of the increased friction force due to wedge action. |

| Flat belt drive is suitable when velocity ratio is up to 4:1. | Higher velocity ratio (up to 7:1) can be obtained by V-belt drive. |

| Slip occurs frequently in flat belt drive. Thus is not a positive drive. | Due to higher friction force for wedge action, slip does not occur at low speed in V-belt drive. However, if load exceeds the rated capacity, then slip may occur. |

| Flat belts are jointed (hinged), so their operation is noisy. | V-belts are endless, so their operation is quite. |

| Flat belt drives are usually suitable for horizontal power transmission. | V-belt drives are preferred for transmitting power in any direction, even when belt is vertical. |

| Flat belts are also relatively cheaper. | V-belts are costlier. |

| Flat belts are commonly used in belt conveyer, saw mills, food industries, etc. | V-belts are commonly used in electric pumps, compressors, machine tools, etc. |

References

- Design of Machine Elements by V. B. Bhandari (Tata McGraw Hill Education Private Limited).

- Theory of Machines by S. S. Rattan (McGraw Hill Education India Private Limited).