Basic purpose of mechanical drive is to transmit torque, motion and power from driving shaft (usually a prime mover like an electric motor) to driven shaft, and also to alter the intensity, direction and speed as per the requirement. There exist several mechanical drives to fulfill varying industrial and machinery requirements. Such drives can be classified into two major categories—positive drive and non-positive drive. A positive drive is free from slippage and thus provides constant velocity ratio. Contrary to this, a non-positive drive cannot provide fixed velocity ratio due to slippage or other similar issues. Each drive has unique advantages over the other one and thus is used in various applications. Gear drive and coupling are examples of positive drive. Chain drive also offers constant velocity ratio if designed and maintained properly. On the other hand, belt drive and rope drive are considered as non-positive drive as they are prone to slip and creep.

Belt drive is one type of mechanical drive where motion and power are transferred from one shaft to another by means of friction between belt and pulleys mounted on each shaft. As friction plays the primary role in power transmission, so it is also called a friction drive. Slip can occur between belt and pulley when load exceeds the rated capacity. Such slippage is not always undesirable as it can inherently protect various machine elements from overloading. On the contrary, chain drive is one engagement type power transmission system that transmits motion and power by means of successive engagement and disengagement chain with sprocket. Being a positive drive, it offers a fixed velocity ratio; however, sometimes fails to protect the system from excessive loading. Various similarities and differences between belt drive and chain drive are given below in table format.

Similarities between belt drive and chain drive

- Both belt drive and chain drive are mechanical drives. Thus they utilize various mechanical elements which must be in physical contact for transmitting power. Apart from mechanical drive, other drives that are frequently used in industries include hydraulic drive, pneumatic drive and electrical drive.

- Both belt drive and chain drive are suitable for transmitting power and motion for medium to larger shaft distance. For shot distance, gear drive is preferred. However, V-belt can be applied for short to medium distance also.

- They can be applied for parallel driver and driven shafts only. They are not suitable for transmitting power between non-parallel shafts. It is worth mentioning that quarter-turn belt can be used for non-parallel non-intersecting shafts.

- Both require frequent adjustment in tension; otherwise slip percentage increases as the belt or chain stretch out with service time.

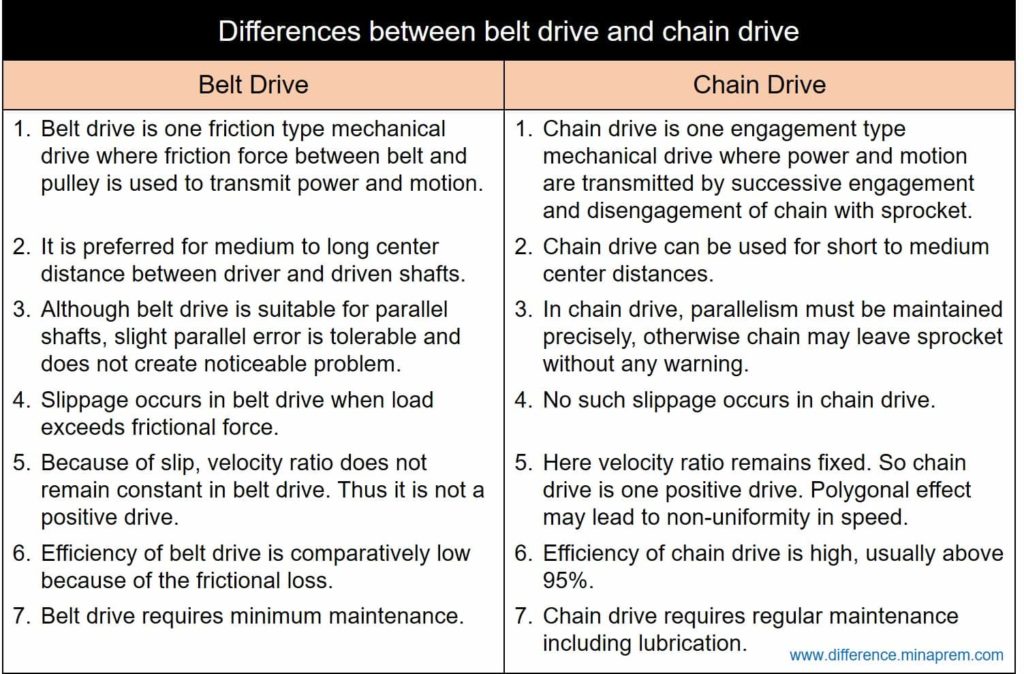

Differences between belt drive and chain drive

| Belt Drive | Chain Drive |

|---|---|

| Belt drive is one friction type mechanical drive where friction force between belt and pulley is used to transmit power and motion. | Chain drive is one engagement type mechanical drive where power and motion are transmitted by successive engagement and disengagement of chain with sprocket. |

| Belt drive is preferred for medium to long center distance between driver and driven shafts. | Chain drive can be used for short to medium center distances. |

| Although belt drive is suitable for parallel shafts, slight parallel error is tolerable and does not create noticeable problem. | In chain drive, parallelism must be maintained precisely, otherwise chain may leave sprocket without any warning. |

| Slippage occurs in belt drive when load exceeds frictional force. | No such slippage occurs in chain drive. |

| Because of slip, velocity ratio does not remain constant in belt drive. Thus it is not a positive drive. | Here velocity ratio remains fixed. So chain drive is one positive drive. However, polygonal effect may lead to non-uniformity in speed. |

| Efficiency of belt drive is comparatively low because of frictional loss. | Efficiency of chain drive is high, usually above 95%. |

| Belt tension is affected by atmospheric conditions and temperature. Thus performance of belt drive also changes with external factors. | Chain drive is usually not affected by atmospheric conditions and temperature. |

| Belt drive requires minimum maintenance. | Chain drive requires regular maintenance including lubrication. |

References

- Introduction to Machine Design by V. B. Bhandari (McGraw Hill Education India Private Limited).

- A Textbook of Machine Design by R. S. Khurmi and J. K. Gupta (S. Chand).

- Theory of Machines by R. S. Khurmi and J. K. Gupta (S. Chand).